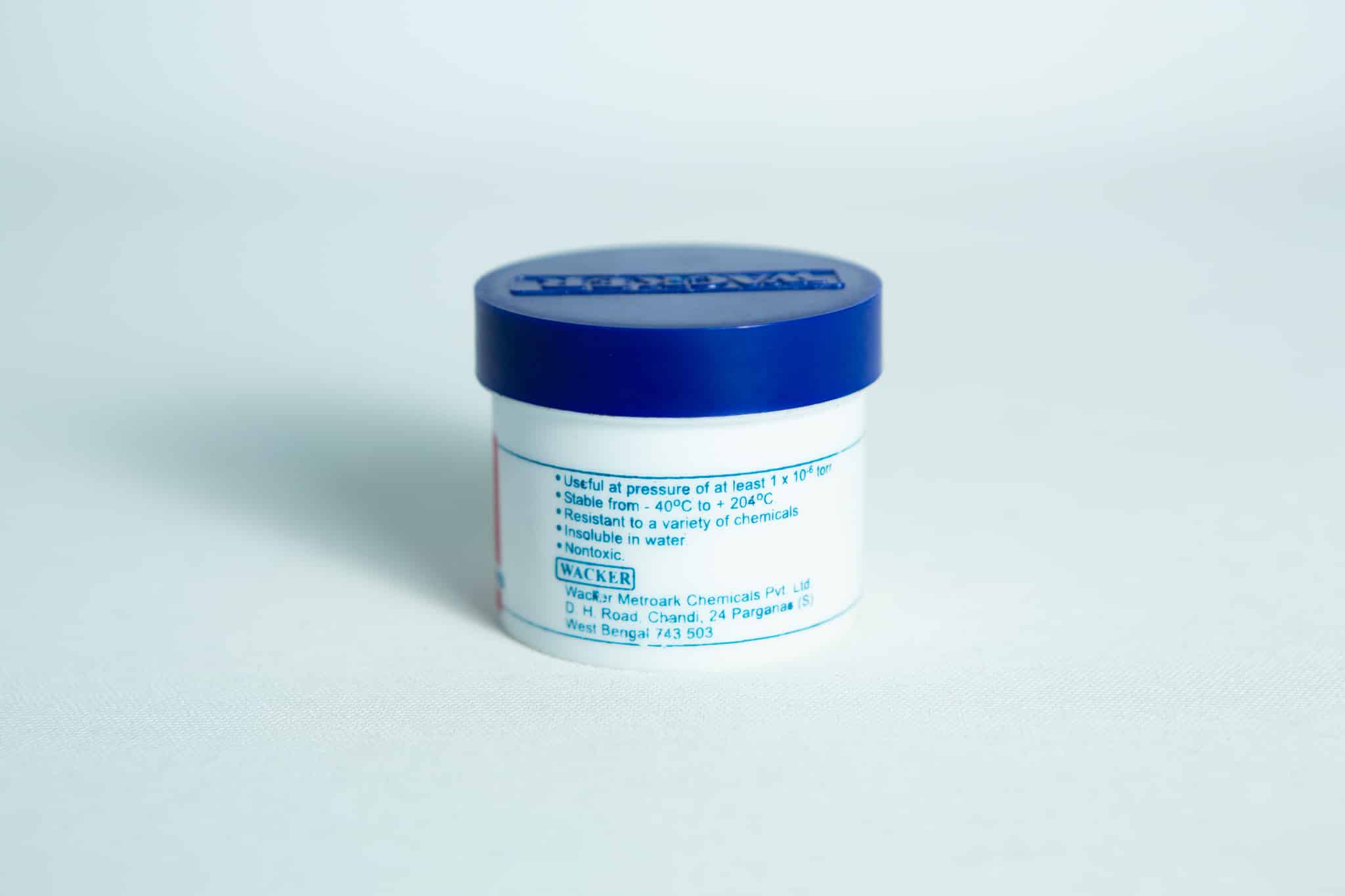

Description

Metroark 211 Compound is a stiff, non-grease-like silicone material. It maintains its consistency over a wide temperature range of—400 °C to 2500 °C. Its low volatility, very low vapour pressure of the base, chemical resistance, relatively constant consistency over a wide temperature range, and sealing ability make it an ideal sealant for high vacuum and high pressure systems and sealant-cum-lubricant for chemical processing equipment.

Net Weight: 50gms

Lubricating the Metal-to-Metal Seal on an All-American Steriliser (for Mycology Use)

All American sterilisers feature a unique metal-to-metal seal, which means they do not use a rubber gasket. To maintain a proper seal and prevent sticking or damage during use, it’s essential to lubricate the contact surfaces where the lid meets the steriliser’s body.

Why Lubrication is Important

- Prevents galling or seizing of the metal surfaces.

- Ensures a tight and even seal during pressure cycles.

- Makes opening and closing the lid easier and safer.

Instructions:

Apply a small amount to a clean paper towel or lint-free cloth.

Rub the lubricant along the top rim of the steriliser body (where it meets the lid). Also, apply a thin layer to the corresponding inner lip of the lid.

Ensure the lubricant is spread evenly without clumps. A thin, even film is ideal, not excess.

Use a clean paper towel to remove any visible excess, leaving just a light film.

How Often to Lubricate:

- Every 3–5 uses or when you notice increased resistance when sealing/unsealing.

- Clean old residue occasionally with isopropyl alcohol before reapplying fresh lubricant.